---

title: spring-9.25x33mm

tags: d3d, ose

disqus: your-shortname

---

:::success

:handshake: Please contribute by directly editing and/or [commenting](https://hackmd.io/c/tutorials/%2Fs%2Fhow-to-use-comments)!

:::

:::danger

Images need to be redrawn and placed under a suitable license (CC BY-SA).

:::

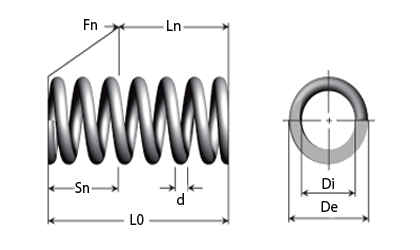

## `spring-9.25x33mm` Compression spring

[:link:](https://www.mcmaster.com/94125K616)

### properties (full spec)

:::info

the following information fully specifies the part

:::

- length (*L0*): 33mm

- OD (*De*): 9.25mm

- wire diameter (*d*): 1.25mm

- spring rate (*R*,*k*): ~ 5.8 $\frac{N}{mm}$

- :flag-us: McMaster: 1.31 lbs/mm = 0.594 kg/mm = 5.85 N/mm

- greater spring rate is "stronger"

### material: spring steel / "music wire"

[:link:](https://www.acxesspring.com/properties-of-common-spring-materials-spring-wires.html)

Typically, suppliers offer two kinds of "music wire" materials. The first option (EN 10270-1) is stronger and should be selected.

:::warning

:bulb: If you are not sure what kind of spring you have: The first option is corrosive and hence has a dull-blackish surface, it also is highly magnetic. The second option is non-corrosive and hence should have a shiny surface and is only slightly magnetic.

:::

#### EN 10270-1 DH ("stronger", corrosive)

:::info

:thumbsup: This is tested and known to work.

:::

- tensile strength R~m~ for d=1.25mm: 2150-2380 MPa

- stress profile: hight static, medium dynamic

- good fatigue life (due to high tensile strength) [:link:](https://www.leespring.com/materials-finishes-and-plating#part-453021)

- highly magnetic

- elastic modulus (*E*): 206 MPa

- shear modulus[:link:](https://en.wikipedia.org/wiki/Shear_modulus) (*G*,$\mu$): 81.5 MPa

- max. 121 ºC (250 ºF)

- high-carbon steel alloy, cold drawn

- norms

- :flag-us: ASTM A-228

- :flag-eu: EN 10270-1 DH (= **D**ynamic **H**igh ?)

- :flag-de: DIN 17223, Klasse D

- "hohe statische, mittlere dynamische Beanspruchung"

[:link:](https://www.sanyosteel.com/files/DIN/DIN%2017223-Part%201.pdf)

#### EN 10270-3 1.4310 ("weaker", non-corrosive)

:::info

:fire: This is untested!?

:::

- tensile strength R~m~ for d=1.25mm: 1850-2300 MPa

- 302NS: 1850-2130 MPa

- 302HS: 2000-2300 MPa

- elastic modulus (*E*): 185 MPa

- shear modulus[:link:](https://en.wikipedia.org/wiki/Shear_modulus) (*G*,$\mu$): 70 MPa

- slightly magnetic

- norms

- :flag-us: 301, 302NS, 302HS

- :flag-eu: EN 10270-3

- :flag-de: Werkstoffnr. 1.4310

- ISO: X10CrNi18-8

### reference suppliers

:::info

these suppliers provide good information and specs, they are not necessarily cheap

:::

:flag-us: [McMaster-Carr](https://www.mcmaster.com/94125K616)

| [The Spring Store](https://www.thespringstore.com/pc049-360-10500-mw-1299-c-n-in.html?unit_measure=me)

| [lee Spring (LCD125EB 03 M)](https://www.leespring.com/compression-springs)

:flag-de: [Sodemann (stronger, 12170)](https://www.sodemann-federn.de/12170)

| [Sodemann (stronger, 1m)](https://www.sodemann-federn.de/19100)

| [Gutekunst (stronger, D-198)](https://www.federnshop.com/de/produkte/druckfedern/d-198.html)

| [Gutekunst (stronger, 1m, KM-3280)](https://www.federnshop.com/de/produkte/druckfedern/km-3280.html)

| [Gutekunst (weaker, VD-198)](https://www.federnshop.com/de/produkte/druckfedern/vd-198.html)

| [Schweizer (only B2B, DF-1843)](https://www.schweizer-federshop.de/bsf02gri.aspx)

### technical drawings and visualizations

:::success

Di = De - 2*d

:::

:flag-de: [data sheet](https://www.federnshop.com/de/datenblatt/gk-federnshop_datenblatt_druckfeder_d-198.pdf)

Sign in with Wallet

Sign in with Wallet